Vibration monitoring devices use accelerometers to measure changes in amplitude frequency and intensity of forces that damage rotating equipment.

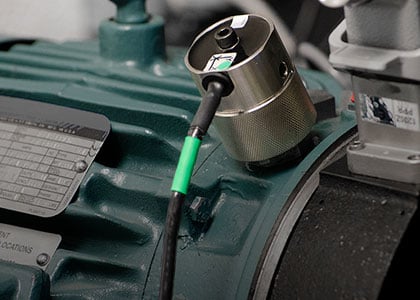

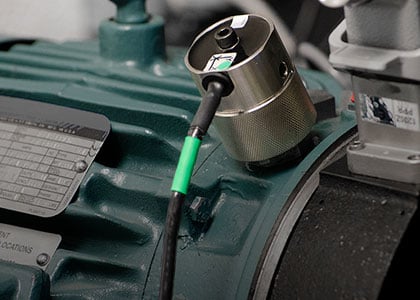

Bearing vibration sensor.

Using the same vibration monitoring technology you can detect and prevent expensive machine damage in real time.

Wirelessly access stored data through any smart phone or tablet during routine inspections.

This intelligent vibration sensor continuously trends and stores overall vibration temperature and bearing condition in 3 directions.

Although vibration feedback is highly desirable proper training is important due to the complexity in data collection and interpretation.

This measures velocity mm sec peak or rms to detect unbalance and problems with structural rigidity and or foundation.

The last type of vibration sensor we will discuss is an eddy current or capacitive displacement sensor.

Typical applications demand vibration measurements in the horizontal vertical and axial direction on both the inboard and outboard motor bearings.

Motors gearboxes and belts.

For vertical measurement sensors should be located on the motor and pump drive end bearings.

Detect mechanical and electrical motor faults with vibration monitoring instrumentation.

Vibration sensors help make sure the bearings motors and fans in water pumps and condensers operate smoothly providing advanced warning of potential issues if readings start to get a bit rough.

Vibration transmitters and sensors detect damaged bearings unbalance in drives and rotating machine parts.

Monitoring vibration on induction motors is at the core of any predictive maintenance program.

Physical characteristics such as temperature rating size and connector orientation are also considerations.

Eddy current sensors are non contact devices that measure the position and or change of position of a conductive component.

The ifm product range includes vibration transmitters vibration sensors accelerometers and evaluation electronics.

The abb ability smart sensor for mechanical products is an easy to use wireless sensor which monitors the health of dodge mounted bearings and gear reducers allowing users to reduce downtime improve reliability and operate safely.

Studying vibration measurements allows teams to discover imbalance looseness misalignment or bearing wear in equipment prior to failure.

For horizontal measurement vibration sensors should be mounted on the motor bearings and pump bearings.

The sensor has a probe which creates an alternating current at the tip of.